Bow Couplings for Dredgers

Straatman designs and manufactures heavy-duty bow coupling systems for hopper dredgers worldwide. Our bow couplings enable safe, fast and controlled bow discharge under extreme marine conditions, with minimal maintenance and maximum operational uptime.

From concept and engineering to production, Straatman delivers a complete bow discharge solution, tailored to your vessel and dredging operation.

What is a Bow Coupling?

A bow coupling is a critical mechanical connection installed in the bow of a hopper dredger. It connects the onboard discharge pipeline to the external bow discharge system, enabling the safe and efficient discharge of dredged material.

Straatman bow couplings are engineered to:

- Absorb high mechanical loads

- Compensate for misalignment and movement

- Operate reliably under pressure and harsh marine environments

Bow Couplings Designed for Hopper Dredgers

Straatman bow couplings are purpose-built for trailing suction hopper dredgers and similar vessels where reliability, safety and uptime are non-negotiable.

Typical applications:

- Bow discharge of dredged material

- Hopper dredgers operating in ports, coastal and offshore environments

- Newbuild vessels and retrofit projects

Customization & options

Our bow discharge installation can be customized with several options to fit specific dredging needs:

- Integrated service frame, a stainless steel frame for easy inspection and maintenance

- Rainbow unit, fixed or insert-type nozzle for material discharge over water

- Flange connections, ensuring easy integration with different pipeline setups

- Wear-resistant liners, protection for a longer system lifespan

- Chain guides & safety features, additional stability and secure operation

- Hoisting system, special lifting mechanisms for handling the bow coupling

- Custom foundations, designed for split hopper dredgers and specialized dredging vessels

Safe and efficient operation

- Smooth connection and disconnection during discharge operations

- Designed with the safety of the crew and the vessel in mind

- Proven design with minimal wear components

- Easy access for inspection and servicing

Technical Specifications (Indicative)

Exact specifications depend on vessel design and project requirements.

- Diameter range: approx. 350 – 1100 mm

- Pressure rating: typically 10 – 30 bar

- Rotation: >360° continuous rotation possible

- Angular movement: up to ±15° (project-specific)

- Materials: high-strength steel, marine-grade components

- Design life: engineered for long-term dredging operations

Detailed datasheets and drawings available on request.

Engineered, Manufactured and Tested In-House

Straatman controls the full process:

- Mechanical engineering and system design

- In-house manufacturing facilities and assembly

- Factory acceptance testing

This guarantees:

- Consistent quality

- Short communication lines

- Customisation without unnecessary complexity

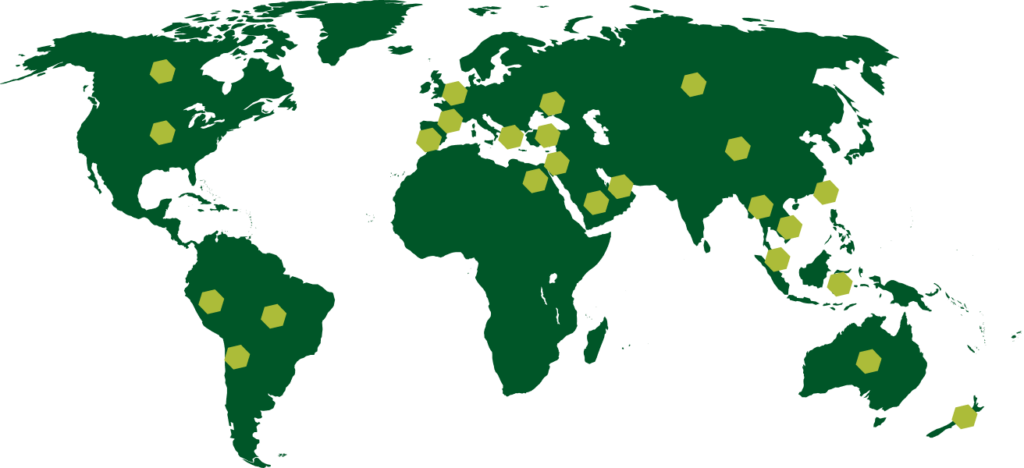

Proven Technology, Trusted Worldwide

Since we invented the bow coupling, it has set the benchmark for modern dredging technology. Straatman bow couplings are used on dredgers operating across Europe, the Middle East, Asia and beyond. They are trusted by leading dredging contractors because:

- They perform reliably under real-world conditions

- They integrate seamlessly with existing dredging systems

- They reduce downtime and operational risk

Let’s discuss your Dredging project

- Specialist in dredging systems

- Proven solutions used in demanding dredging environments

- Over 65 years of experience

- Dutch Engineering and high-quality manufacturing

nl_NL

nl_NL