Quick Release Ball Joints

The Straatman Quick Release Ball Joint is designed for safe, quick and controlled pipe disconnection in critical dredging operations. It allows operators to disconnect pipelines reliably when timing, and safety are key.

Purpose-Built for Dredging Operations

Quick Release Ball Joints are used in dredging systems where pipelines must be disconnected efficiently without compromising safety or system integrity.

Typical applications include:

- Dredging pipelines under pressure

- Situations requiring fast or emergency disconnection

The female part of the quick release ball joint (also known as a pinch ball joint) is positioned on the dredger or pontoon and the male part is connected to the floating pipeline or hose. The quick release ball joint can be operated by hydraulic cylinders. For the smaller sizes, our quick release ball joints can be operated manually.

COnstruction quick release ball joint

It consists of three main parts: the female part, the male part and the retaining ring. The retaining ring couples the male part to the female part. The retaining ring is executed in two parts and is hinged in the female part.

Technical specifications

- For inside pipe diameters: ø 300 – ø 1.100 mm.

- Max. swivel angle male part: 20° (standard)

- Max. operating pressure: 6 – 45 Bar

Available options

In addition to a wide range of standard designs, Straatman Quick Release Ball Joints can be supplied with the following options to suit specific operational requirements:

- Hydraulic operation, for controlled and safe disconnection, reducing manual intervention.

- Higher operating pressures. Designed for applications requiring increased pressure ratings.

- Deviating swivel angles. To accommodate pipeline misalignment and vessel movement

- Exchangeable liners. Allowing fast replacement and reduced maintenance downtime.

- Catch ring or custom-made cone. For improved guidance during connection and disconnection,

Options and configurations are defined during engineering to ensure safe and reliable operation.

Let’s discuss your Dredging project

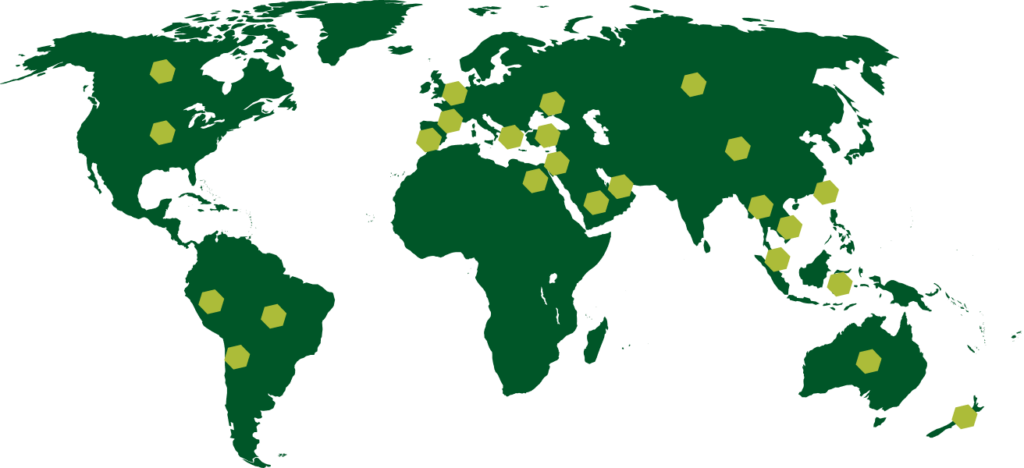

- Specialist in dredging systems

- Proven solutions used in demanding dredging environments

- Over 65 years of experience

- Dutch Engineering and high-quality manufacturing

nl_NL

nl_NL