Straatman Dredging & Construction designs and manufactures turning glands for dredging and marine applications where rotation, pressure and reliability come together. Our turning glands provide a robust, leak-tight sealing solution for rotating pipe connections under demanding operating conditions. As this is even possible under pressure and heavy conditions, our turning glands ensure more safety and better maneuverability.

What Is a Ball Turning Gland?

A ball turning gland is a mechanical sealing solution used in rotating dredging pipelines. It allows controlled rotation of the pipe while maintaining a pressure-tight seal — essential for reliable dredging operations.

Turning glands are typically applied where:

- Pipelines must rotate relative to fixed sections

- Pressure and abrasive materials are involved

- Leakage or downtime is not an option

Designed for Dredging Applications

Straatman turning glands are engineered specifically for dredging environments, where sand, slurry, pressure and continuous movement put systems under constant stress.

Typical applications of turning glands:

- Dredging pipelines with rotational movement

- Hopper dredgers, cutter dredgers and stationary dredging installations

- Newbuild and retrofit dredging systems

technical overview

Specifications vary depending on the application and project requirements.

- For inside pipe diameters: ø 200 – ø 950 mm.

- Maximum swivel angle : 3°

- Turning angle : > 360°

- Operating pressure (single ball type): 10 – 36 Bar

Let’s discuss your Dredging project

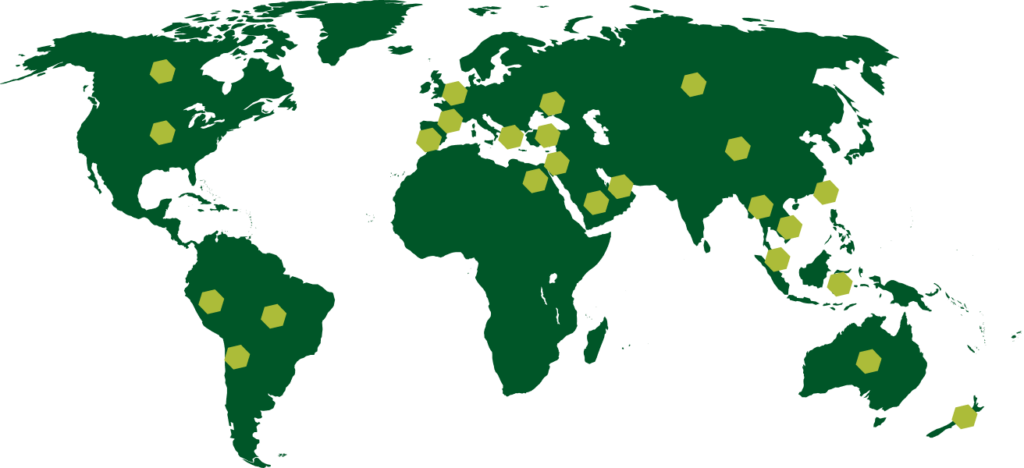

- Specialist in dredging systems

- Proven solutions used in demanding dredging environments

- Over 65 years of experience

- Dutch Engineering and high-quality manufacturing

nl_NL

nl_NL